Metrology Solutions

Overview

Prior PLM Medical provide Metrology Solutions, which, in conjunction with our manual and semi automated inspection systems and CMM fixtures, facilitate the precise location and measurement of moulded components. With a focus on quality, functionality, reliability and ease of use, our inspection systems are used across the world, saving our customers time, and have become a pillar of their quality control systems.

- Diverse engineering and systems services experience

- Proven success with OEM, Tier 1, 2 & 3 suppliers

- Onsite integration capabilities and experience

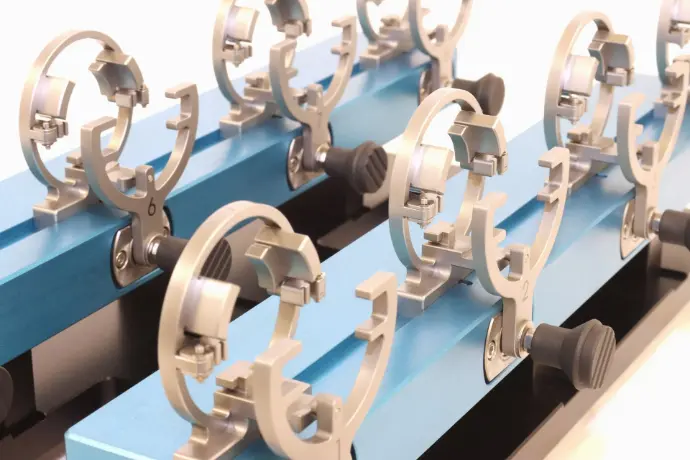

CMM Fixtures

Our custom CMM fixtures are designed to hold components securely without causing distortion while allowing for both measurement by CMM and Vision Systems. The precise machining of the fixtures ensures consistent component positioning, minimising measurement variation. The optional palletisation of the fixtures, using System 3R Pallets, enable each fixture to be rotated in 90° increments, enhancing versatility and ease of use. The Modular design enables multiple single impression fixtures to be mounted on a single, self-contained station.

We offer both single and multi impression CMM fixtures to suit your component measurement needs. The fixtures are constructed from pre-hardened chromium steels to ensure many years of maintenance-free operation.

Manual & Semi-Automated Inspection Systems

Priors Metrology Solutions division, specialises in IPC automated solutions, from initial concept and manufacture through to validation and production support. We engineer comprehensive metrology solutions, drawing on a wealth of technical expertise and experience in robotic and manual applications.

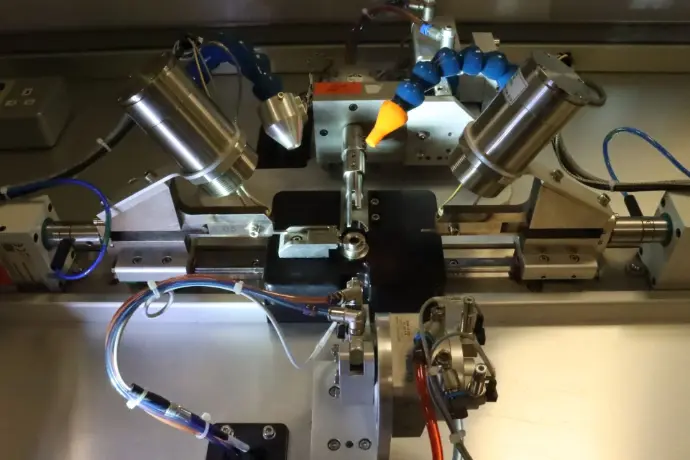

Priors Automated IPC systems are recognised internationally for their ease of use. "One touch" measuring eliminates complex staff training while multiple simultaneous measurements increase efficiency. The measurement results are sent directly to client's statistical process control software

Lab Equipment

Autoinjectors and Pre-Filled Syringes, represent a rapidly growing segment of the medical product market. To ensure these devices function reliably and safely, detailed testing is essential. This testing is conducted by both autoinjector manufacturers and the pharmaceutical companies that fill them. Critical factors in this process include the reproducibility and traceability of test results, as well as minimising operator influences.

At Priors we design and manufacture customer test fixtures for Auto-Injectors that test the following parameters:

- Penetration Depth

- Dose Efficiency

- Hold Force

- Activation Force

- Cap Removal Force (With & Without RNS)

- Delivery Time

- Dose Accuracy

- Other parameters per customer request

Test Fixtures for Pre-Filled Syringes, Cartridges and Vials.

- Diluent Cap Break Force

- Needle attachment/ detachment torque

- Vial Cap removal force

- Needle shield removal force

- Vial Penetration Force

- Break Loose & Glide Force

- Withdrawal Force