Laser Welding

Overview

The repair of any damaged tool invariably starts with the replacement of missing material, and there is no better way to do that than to use the laser welding process. This is why Priors have established a centre of laser welding excellence within the MRO division.

Priors operate 3 German manufactured Alpha laser welding units, these powerful state-of-the-art pulsed laser systems, allow our skilled laser welding technicians to rebuild complicated shapes in 5 axis, they can coat an entire damaged surface or can deposit a single spot of metal less than 0.05 mm in diameter. The optical system of the Alpha Laser Welding unit is made by the world-leading lens makers Leica and gives our technicians unparalleled real time observation and control of the welding process. A built in Leica camera system allows the technician the ability to share still or video images of the welding process with the customer.

Quality

Priors operate an intense maintenance / preventative maintenance schedule on our Laser welding machines which maximises the performance of our equipment and results in optimum weld quality.

As part of our ongoing commitment to

quality, learning and customer support, a detailed log of every job done

by our welding team ensures that we know the type / batch of material added and

the laser parameters used during the welding process. This attention to detail

gives us an invaluable ever-growing database, which allows us to monitor the

performance of every repair we have ever completed over a tools life.

Materials

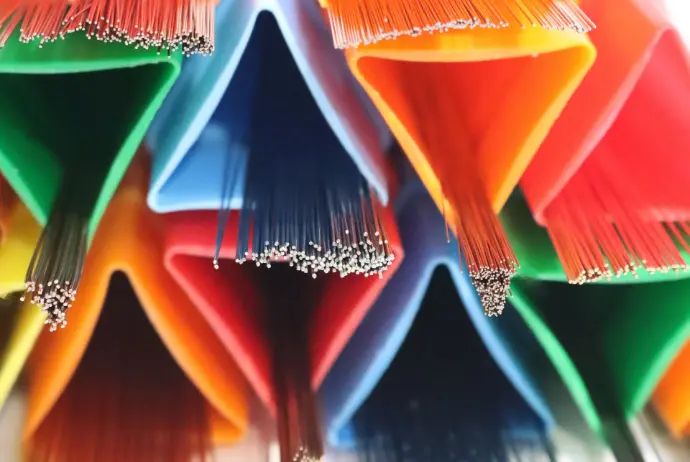

Priors ongoing programme of expanding our Laser welding services to fulfill our customers’ requirements means that we now offer the welding of all steel grades, as well as Aluminium, Moldmax, Bronze, Brass, Copper as well as many specialist grades of steel, and Titanium alloys. Different materials require specific welding wires to ensure strong durable welds and prevent issues such as cracking or poor fusion, to facilitate this, Priors carry an extensive range of welding wires in stock.

The hardness of a steel repair can be tailored from 28-64Hrc. All our additive welding wire is sourced through our reputable European partners, guaranteeing quality and reliability.