Maintenance, Repair & Overhaul

Overview

An essential aspect of the Product Life Management for any moulding project is Maintenance Repair and Overhaul (MRO) of the moulding tools. Good tool management can optimise moulding production, minimise component quality rejection and importantly, extend the life of your valuable tools.

Priors have a dedicated MRO support team who specialise in the repair of complex and precise medical moulds. From small cassette moulds, to large multicavity 2 shot moulds or hot runner systems, all moulding tools are catered for.

Maintenance

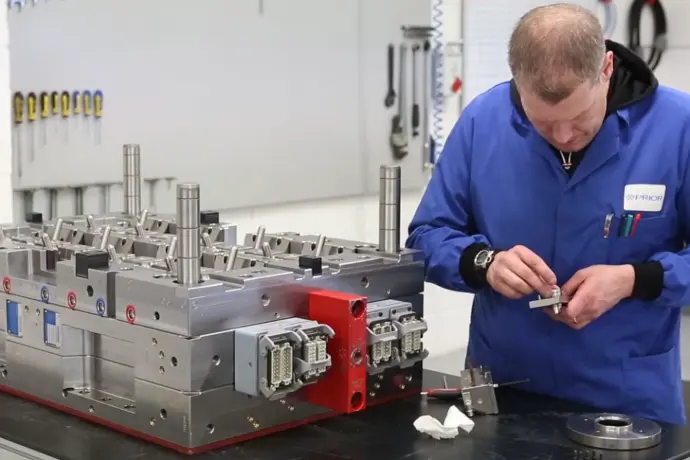

Our qualified technicians will assess your moulding tool and issue a full report outlining the necessary works required. Any damage or wear is imaged and documented before being quoted for. Work is carried out to the highest industry standards by our team and if required completed tools can be trialed in our moulding facility before being returned.

Repair

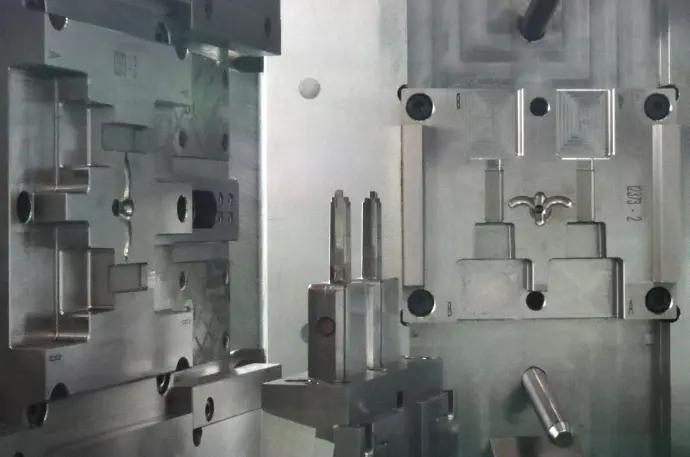

Our clients from around the world send moulding inserts for repair at our specialist repair facility.

We carry out all types of cavity modification and die repairs. Our MRO technicians can bring your moulding inserts back to their original tolerances. On completion, repairs can be measured, inspected and certified.

Types of repairs include:

- Gate wear

- Shut off damage

- Out-gassing corrosion

- Split-line damage

- Water lane corrosion

- Modifications

- Hot Runner systems

- Large scale overhauls

Overhaul

Often tools which seem to be at the end of their operational life can have their useable lives extended by a full overhaul from our team. Worn components can be replaced with cavities and shut outs repaired. If necessary, Priors can also modify cavity details to facilitate product evolution and allow older tools to retain relevance, beyond their expected lives.

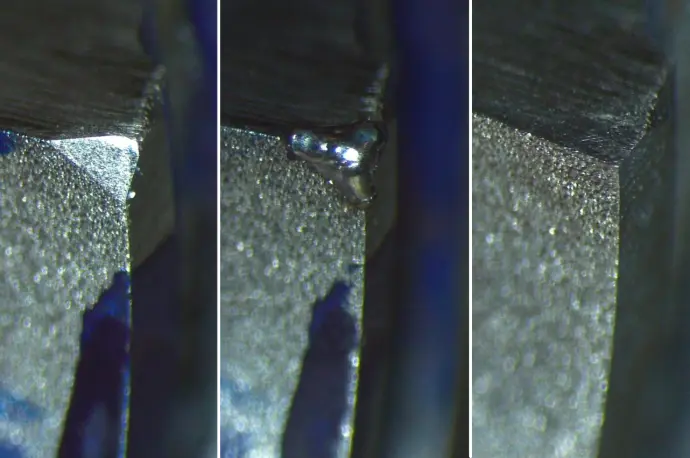

Laser Welding

Priors operate 3 German manufactured Alpha laser welding units, these powerful state-of-the-art pulsed laser systems, allow our skilled laser welding technicians to rebuild complicated shapes in 5 axis, they can coat an entire damaged surface or can deposit a single spot of metal less than 0.05 mm in diameter. The optical system of the Alpha Laser Welding unit is made by the world-leading lens makers Leica and gives our technicians unparalleled real time observation and control of the welding process. A built in Leica camera system allows the technician the ability to share still or video images of the welding process with the customer.