Biomedical Engineering

Pioneering Partners In The Development of Sustainable Respiratory Medicine

If you don’t have asthma, the chances are that you know someone who has. According to the World Health Organisation, over 300 million people worldwide suffer from asthma and other respiratory diseases, such as chronic obstructive pulmonary disorder. Yet these diseases are surprisingly hard to treat directly, because common inhalers – either pressurised metered dose inhalers (PMDIs) or dry powder inhalers (DPIs) – often only deliver 10–20% of the released medicine to the lungs. Our team have been studying and working with inhaler devices for two decades and are currently approaching this issue along a number of key themes.

Understanding Low Drug Efficacy Rates In Patient Administered Medicine

Computational Fluid Dynamics (CFD) coupled with Discrete Element Model (DEM), or CFD/DEM for short, is an ideal early-stage Dry Powder Inhaler (DPI) development tool that Prior PLM Medical uses to help speed up design concept selection.

DPI functional parameters such as pressure drop and particle deagglomeration can all be tuned using CFD/DEM simulations. But how do you know if your model is accurately representing reality?

The answer is model correlation, and to do this, Prior PLM Medical manufacture optically clear USP Induction port geometry which allows us to take high speed video of the DPI plume as it exits the device and travels into the USP IP. By then applying in-house designed image filtering software, we can accentuate the particle plume even more for comparison purposes.

Lowering The Environmental Impact of Inhaler Propellants

Scientists at Prior PLM Medical have been using High-energy synchrotron X-rays for over 12 years, as this allows the examination of the internal workings of inhalers and other medical devices during actuation in a non-invasive manner. X-rays reveal the movement of components inside the dose counters, trigger mechanisms and dosing events, allowing interactions to be observed during normal use, or even misuse. We have a custom-built Schlieren optical rig to measure plume geometry post actuation on inhaler devices. These high-speed imaging techniques are used to study propellant behavior.

Solving The Recycling Challenge

As incoming changes to environmental law force companies to rethink product design and production, Prior PLM Medical are well positioned to help your organisation evaluate new materials and processes. Our team work hand in glove with our rapid prototype tool manufacturing section, supported by our in-house metrology and pilot manufacturing cleanroom, enabling a smooth transition to more environmentally sustainable materials.

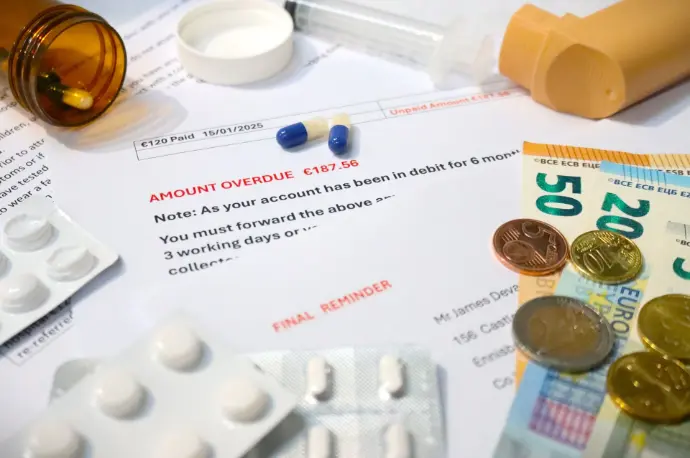

Reducing Costs for Healthcare Payers

Prior PLM Medical are passionate about the development of self- administered respiratory medicine that is affordable to all. Challenges relate to the increasing costs of current propellants, as well as a general demand to reduce the cost of self-administered drug delivery devices. Priors R&D and product development work hard to fulfill the need for new device/drug combinations that satisfy cost and sustainability demands, without compromising effectiveness or availability.