Injection Mould Solutions:

Prior PLM Medical has 30 years experience in producing complex injection moulding solutions. The knowledge and expertise gained from this experience allows us to create optimised solutions based on our customers’ needs. Our first step in every project is to fully understand and define customer requirements. At Prior PLM Medical we understand that customer communication is essential to ensuring that key project requirements are successfully met, irrespective of the technical challenges or mould technologies involved. To ensure quality, we have invested in the latest software systems, CNC technology, and quality control systems, certified in accordance with ISO 9001:2008. At Prior PLM Medical, we are committed to ensuring that our clients’ expectations are always met.

-

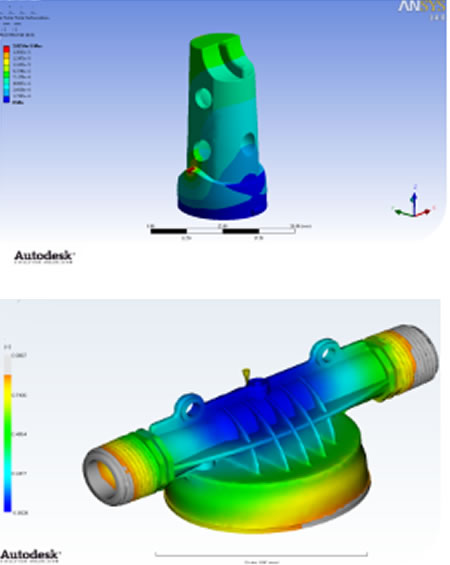

3D Software Analysis

At Prior PLM Medical, we use the latest CAD, CNC, data management and finite element analysis software including:

At Prior PLM Medical, we use the latest CAD, CNC, data management and finite element analysis software including:- Siemens NX

- Siemens Solid Edge

- Siemens TeamCenter

- Ansys Workbench

- AutoDesk MoldFlow Advisor

Before a piece of steel is touched, designs undergo a thorough feasibility study which may include DFM study, MoldFlow analysis and finite element analysis to ensure design specifications are optimised. This work ensures that risks are minimised and clients are fully informed as to any potential moulding issues prior to mould manufacture.

-

Prototype Moulds

A plastic injection moulding prototype mould can be very important in the development of a new product, offering a fast, low cost tooling solution for producing parts for fit and function testing. Prototype moulds also offer the advantages of testing the moulding process and moulding with the production material, so any process or material based design flaws are discovered early on, saving time and money in development.

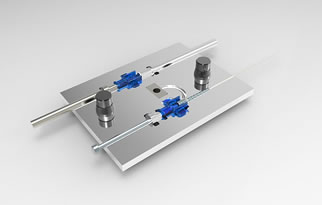

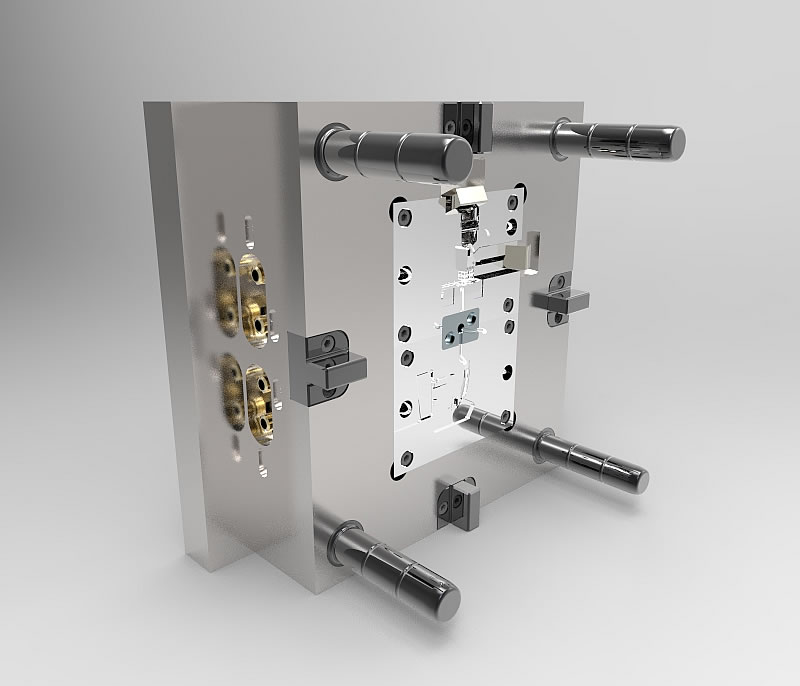

Cassette Moulds

The cassette tool is a modular system that can be configured to suit almost any moulding application. Changes can be made to the component as desired at a fraction of the cost of alterations to production tools. This results in a more efficient route to market, with less design changes and ideal for pre-production and R&D tooling. The cassette tool is loaded manually into a cassette mould base for injection. The components are semi-automatically or manually de-moulded. Numerous gate locations can be mould trialled in order to examine component filling. The cassette tool system is suited to small production runs up to 100 shots per shift. Multiple components or often under / over-mould combinations can be moulded in the same cassette. The cassette system is ideal for over-moulding medical tubes, wires, Leurs, etc. With their cassette tooling design solution, customers purchase just a single mould base. An unlimited amount of components can then be produced with a simple cassette change while the tool is still in the machine. Costs and lead times are greatly reduced with this system.

The cassette tool is a modular system that can be configured to suit almost any moulding application. Changes can be made to the component as desired at a fraction of the cost of alterations to production tools. This results in a more efficient route to market, with less design changes and ideal for pre-production and R&D tooling. The cassette tool is loaded manually into a cassette mould base for injection. The components are semi-automatically or manually de-moulded. Numerous gate locations can be mould trialled in order to examine component filling. The cassette tool system is suited to small production runs up to 100 shots per shift. Multiple components or often under / over-mould combinations can be moulded in the same cassette. The cassette system is ideal for over-moulding medical tubes, wires, Leurs, etc. With their cassette tooling design solution, customers purchase just a single mould base. An unlimited amount of components can then be produced with a simple cassette change while the tool is still in the machine. Costs and lead times are greatly reduced with this system.Pre-production Tooling

We specialise in design and manufacture of pre-production tooling used to validate the performance of production tools to their full potential.

We specialise in design and manufacture of pre-production tooling used to validate the performance of production tools to their full potential. -

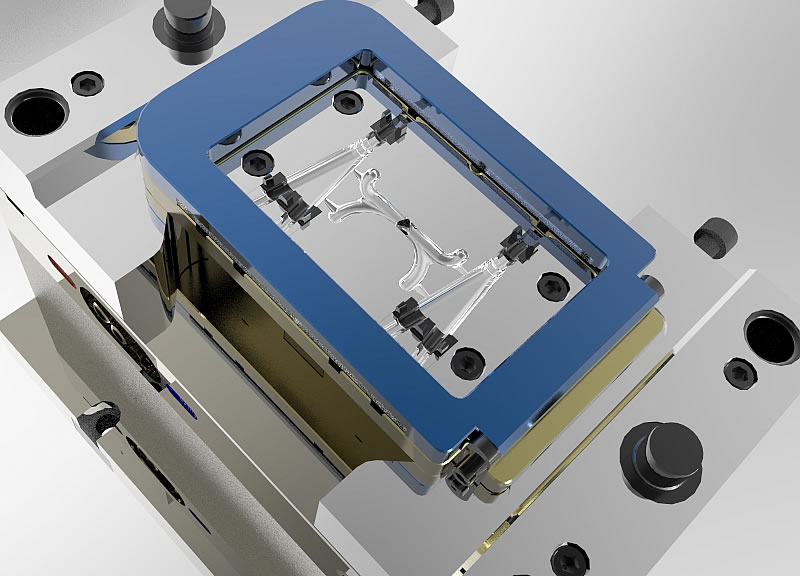

Production Moulds

At Prior PLM Medical, we focus on supplying you with production tooling that maximises reliability and component quality and minimises cycle time and down time. We have an in-depth knowledge in the moulding of sub-miniature and micro components down to 0.0025g. We have pre-engineered solutions for most moulding applications. With our experience in automation, we can automate your process into a fully automated cell, incorporating moulding, de-moulding, inspection, assembly, finishing and any other ancillary processes. We make a special effort to include the latest in moulding, gating and cooling technologies in all of our tooling designs. Such technologies include:

At Prior PLM Medical, we focus on supplying you with production tooling that maximises reliability and component quality and minimises cycle time and down time. We have an in-depth knowledge in the moulding of sub-miniature and micro components down to 0.0025g. We have pre-engineered solutions for most moulding applications. With our experience in automation, we can automate your process into a fully automated cell, incorporating moulding, de-moulding, inspection, assembly, finishing and any other ancillary processes. We make a special effort to include the latest in moulding, gating and cooling technologies in all of our tooling designs. Such technologies include:- Conformal cooling

- Diffusion Welding

- Pressure Transducers

- Temperature Transducers

- Safety Sensors

All production tools undergo a stringent mould tool validation trial on our in-house moulding machines. We can carry out initial component inspections or even do full mould process studies so that your tool is process validated prior to shipping. At Prior PLM Medical, we have extensive experience in the design and manufacture of low and medium volume tools that utilise hot and cold runner systems.

Hot Runner Moulds

Hot Runner Advantages:

- Elimination of the Runner

- Cycle Time Reduction/Lower Processing Costs

- Improved Moulding System Efficiency

- Optimal Part Quality

- Moulding Automation

- Design Flexibility

- Balanced Melt Flow

Cold Runner Moulds

Not all molding applications are suitable for runnerless molding. Some materials are heat sensitive and the time to temperature relationship – especially when the shot size is very small – can be a problem.

Cold Runner Advantages:

- Lower cost

- Less maintenance required

- Wider variety of gating options

-

Technical Moulding

Insert Moulding

A preformed plastic or metal insert is incorporated into the component during the moulding stage or as a post-moulding stage to improve the strength of the moulding or to add features to aid its functionality. When inserts are used during the moulding stage, standard moulding machines can make it difficult for operators to put inserts into their correct place in the tool. For this process, vertical press machines and vertical machines with a rotary table are most effective.

Benefits of Insert Moulding

- Reduced post-moulding operations

- Increased part consistency

- Ease of assembly

- Increased part functionality

- Reduced production time

Micro Moulding

Micro moulding is a very unique injection moulding process requiring a specialized moulding machine capable of delivering high injection speed , high injection pressure, precise shot control, uniform melt temperature and ultra-fine resolution using servo-electric drives and sophisticated controls.

Challenges in micro mould tool construction

- Physical limitation to how small one can mill or EDM materials, established by the geometric characteristics of the feature being formed

- Shear strength of steel needs to resist the forces exerted by cutting head or in the case of EDM, surface finish is eroded beyond an acceptable level

- Mechanical, thermal and chemical properties of the material being formed are affected by these challenges.

Prior PLM Medical has delivered production micromolding solutions for medical and micro fluidic applications requiring specialised polymers such as polyetheretherketone (PEEK), Pebax, and bio-resorbable materials. Unique requirements not found in larger parts can be accommodated through innovative micro mould design, the latest generation of micromachining processes, and an in-depth understanding of the micro injection moulding process.

Multi-Shot

Prior PLM Medical have extensive experience in designing and building high quality moulds for multi-shot and 2-shot injection moulded plastics for a wide range of applications.

Multi-shot plastic injection moulding and 2-shot plastic injection moulding is an efficient and cost effective method for moulding custom plastic parts with two or more plastic resins or colours in one operation.

In multi-shot and 2-shot custom plastic injection moulding, plastic polymers from two or more injection units are applied through independent nozzles on one injection moulding machine to produce custom plastic parts.The multi-shot and 2-shot plastic injection moulding technology enables:

- Multi-colour, multi-material and multi-component parts

- New and wider range of designs

- More complex parts and reduced cost

- Increased production, handling and assembly efficiencies and the associated cost savings

- Lower part cost

- Enhanced product features and appeal, including tactile, ergonomic and aesthetics

- Elimination of secondary process for logos, graphics and text

Unscrewing

Prior PLM Medical have designed and constructed many Unscrewing Moulds that automatically and quickly mould threaded parts, in single or multiple cavity formation.

Unscrewing Mould Design Types:

- Single Cavity

- High Volume Multiple Cavity

- Cold Runner

- Hot Runner

- Partial Hot Runner

- Ejector Pin Ejection

- Stripper Plate Ejection

- Hydraulic Cylinder Activated

- Hydraulic Motor Activated

- Electric Servomotor Activated

- Press Opening Activated

-

Moulding Ancillaries

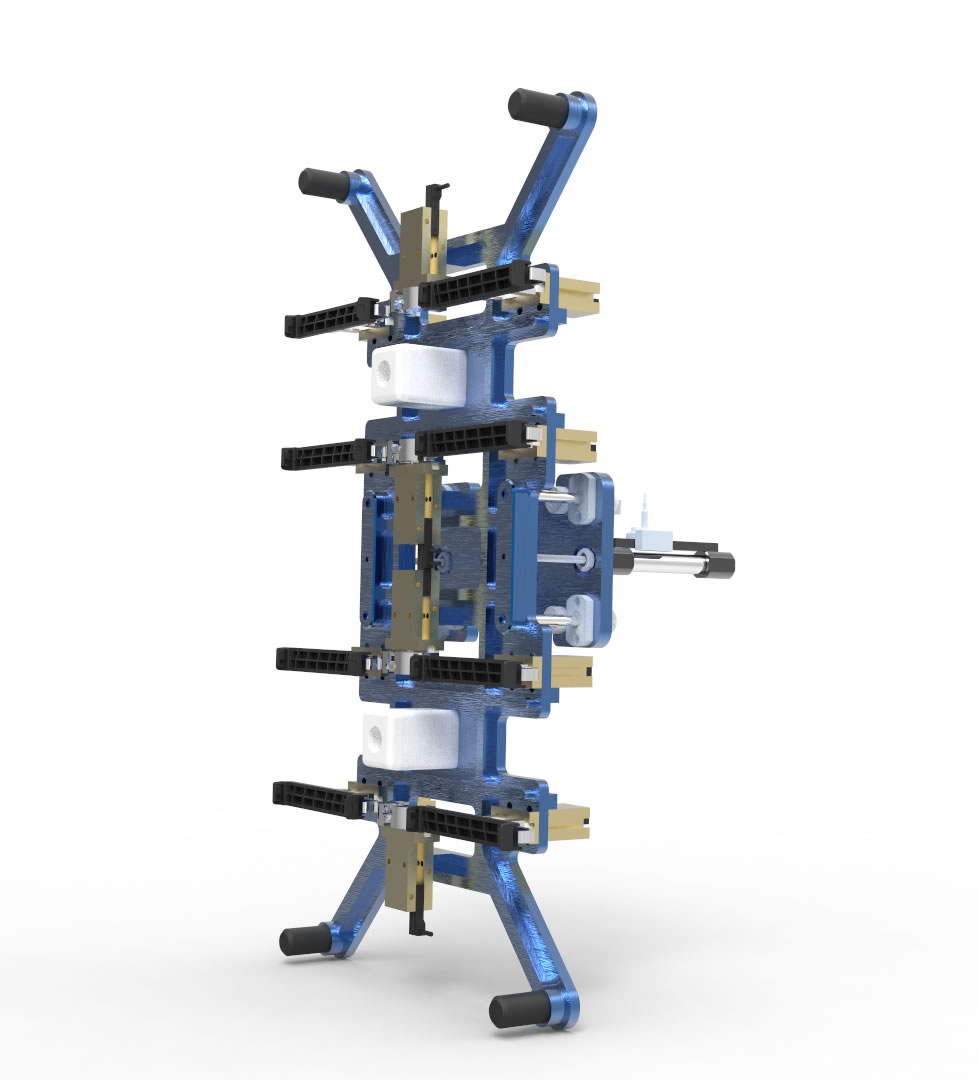

End Of Arm Tooling (EOAT)

Prior PLM medical also specialises in custom designed, robustly engineered and constructed end of arm tooling (EOAT) and grippers to compliment the latest robotics used in horizontal and vertical plastic injection moulding, insert moulding, in-mould decorating and in-mould labelling. Our end of arm tooling grippers and robotic end effectors are custom designed and built for increased speed and accuracy. Typical applications:

- Part/Sprue Picking

- Insert Loading (including high tolerance)

- Part Confirmation (vacuum or gripper confirm)

- Dual Function & Triple Function (picking & placing)

- Docking (ensuring accurate alignment)

- Gripper Systems (parallel or angular, 2 or 3 jaw)

- Vacuum Cup Systems

- Magnetic

- Quick Change Devices

Palletisation Systems

For certain applications, traditional pallet-based automation systems can be a more suitable choice than robotic automation. While robotic automation is often a more flexible form of automation, Prior PLM Medical have designed and constructed a wide range of palletisation systems for automation approaches that offer speed and high machine utilization rates.

De-Moulding Fixtures

Some components may require removal fixtures which can be supplied to de-mould components as efficiently as possible.

Prior PLM Medical have earned a reputation for delivering top quality, robustly engineered de-moulding fixtures resulting in improved product quality and reduced cycle times for our customers.

The fixtures can incorporate hydraulic, pneumatic or manual clamping and can include features such as correct part seating confirmation, part present confirmation and capability for automatic/robotic loading and unloading.Special attention is given to:

- Ease of loading / unloading

- Clamping force

- Nest rigidity

- Maintenance